I have always wanted a plate rack. But I did not want to spend the money on one. I recently learned how to weld and decided it was time to build my own. A local steel company was having a huge steel sale and for once, it seemed like the stars aligned. I bought 142 pounds of steel and 2 12x12 AR500 plates. Total metal cost, with the AR500 plates was $145. I was beyond excited.

I bought a 3/8 inch angle which I hoped would be strong enough, and it was. I bought DOM for the pivots. Some square tubing. And of course the AR500.

I wanted this to be super portable and I wanted it close to the ground. I have a decent back stop at one of the places I shoot. But the other locations are not as good. So I figured the downward angle of the shots would be helpful.

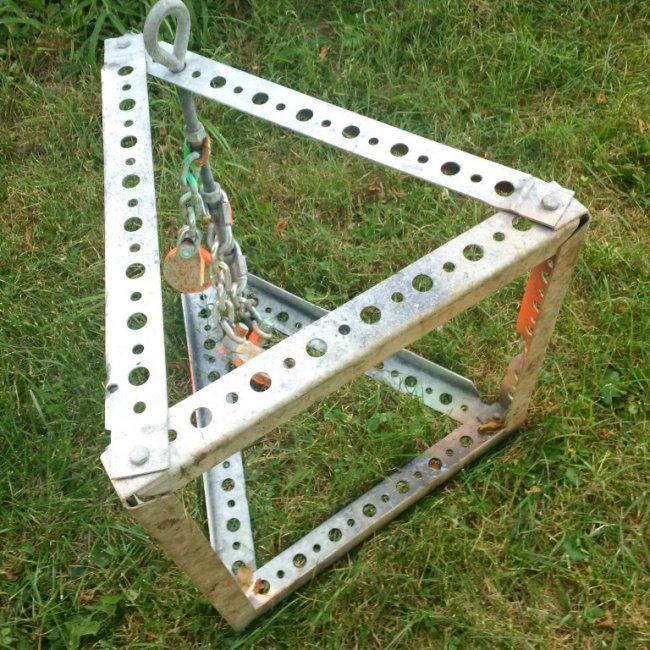

After tacking together the legs and the angle it was starting to take shape.

Next I tacked on the square pieces. These would serve two purposes. One, to push the plate out from the angle, so the plates would sit on an angle. Two, to mount the DOM.

After carefully cutting the AR500 with a plasma cutter, I got those welded and test fit.

I thought my welding was pretty good for just learning! It was also time to finish welding everything together. The snot on the plate came off after it was shot a few times.

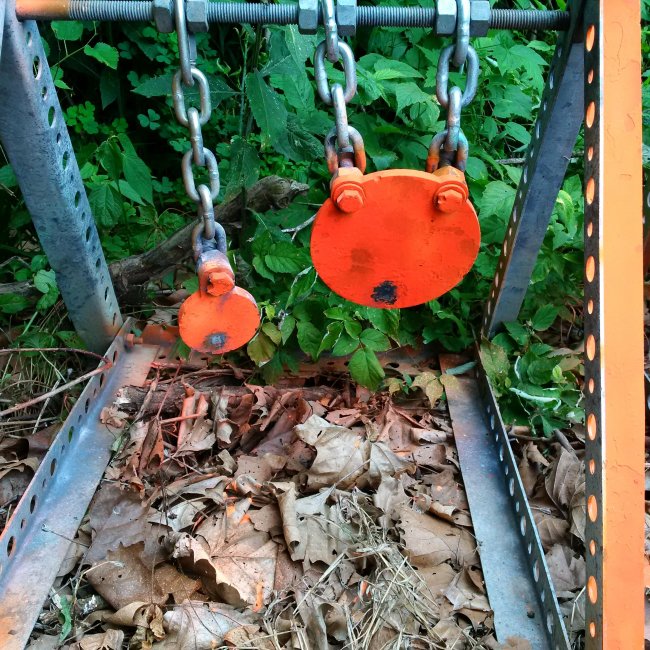

I then added a reset.

She was ready for her maiden voyage. I figured I would paint it later. I was very pleased how easy it was to take apart. I could do it myself, if I needed to. It set up as easily as I imagined, I love it when a plan comes together.

The first shots proved very promising. We ended shooting it with 9, 40, 45. Everything looked great. We even got silly and shot it with steel core 5.45. No problem at all! Shooting with a buddy made it fun. The angle held up great to all the pistol caliber rounds. It even stopped the 5.45. Yes there was a hole, but it did not pass all the way through.

Here are two videos, I wish I knew how to make them, so you did not have to click the link. The safety worked very well in the first video.

[video]http://vid1382.photobucket.com/albums/ah243/zogs19/IMG_1426.MOV_zpsxvdeeomi.mp4[/video]

[video]http://vid1382.photobucket.com/albums/ah243/zogs19/IMG_0090.MOV_zpsoheyrjsh.mp4[/video]

Even the wife had fun, but of course would not listen to my suggestions for closed toe shoes. 10 years later you would think I would have realized she knows more than me….

I could not be happier. It is not as pretty as one I would have purchased from a retailer. For well under $200, I finally have a very functional plate rack, that appears will last me for a very long time.

I bought a 3/8 inch angle which I hoped would be strong enough, and it was. I bought DOM for the pivots. Some square tubing. And of course the AR500.

I wanted this to be super portable and I wanted it close to the ground. I have a decent back stop at one of the places I shoot. But the other locations are not as good. So I figured the downward angle of the shots would be helpful.

After tacking together the legs and the angle it was starting to take shape.

Next I tacked on the square pieces. These would serve two purposes. One, to push the plate out from the angle, so the plates would sit on an angle. Two, to mount the DOM.

After carefully cutting the AR500 with a plasma cutter, I got those welded and test fit.

I thought my welding was pretty good for just learning! It was also time to finish welding everything together. The snot on the plate came off after it was shot a few times.

I then added a reset.

She was ready for her maiden voyage. I figured I would paint it later. I was very pleased how easy it was to take apart. I could do it myself, if I needed to. It set up as easily as I imagined, I love it when a plan comes together.

The first shots proved very promising. We ended shooting it with 9, 40, 45. Everything looked great. We even got silly and shot it with steel core 5.45. No problem at all! Shooting with a buddy made it fun. The angle held up great to all the pistol caliber rounds. It even stopped the 5.45. Yes there was a hole, but it did not pass all the way through.

Here are two videos, I wish I knew how to make them, so you did not have to click the link. The safety worked very well in the first video.

[video]http://vid1382.photobucket.com/albums/ah243/zogs19/IMG_1426.MOV_zpsxvdeeomi.mp4[/video]

[video]http://vid1382.photobucket.com/albums/ah243/zogs19/IMG_0090.MOV_zpsoheyrjsh.mp4[/video]

Even the wife had fun, but of course would not listen to my suggestions for closed toe shoes. 10 years later you would think I would have realized she knows more than me….

I could not be happier. It is not as pretty as one I would have purchased from a retailer. For well under $200, I finally have a very functional plate rack, that appears will last me for a very long time.