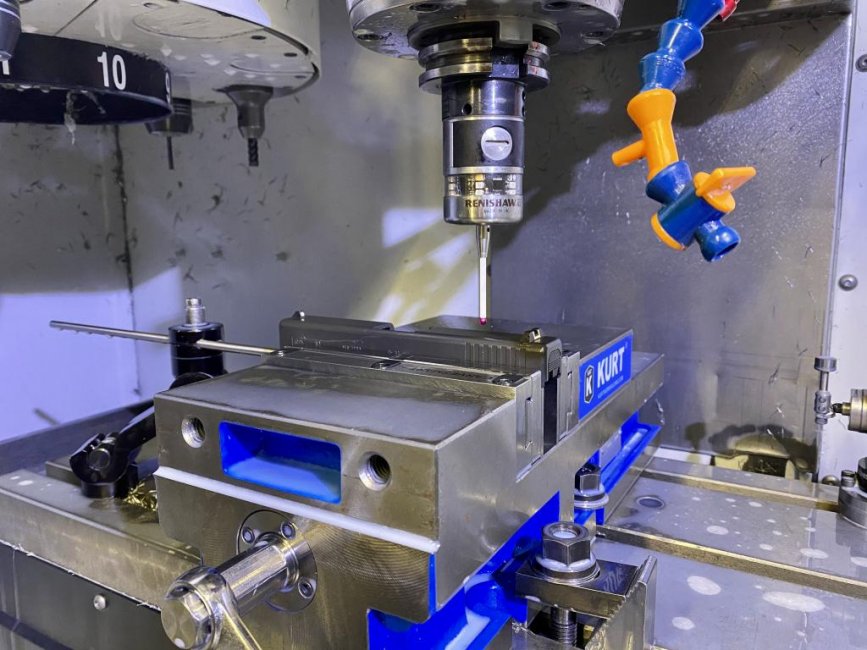

So I milled my Glock 19 slide .03” deep and left locating bosses for the holes in the bottom of the vortex venom. My slide was straight and flat in the vice within .002” (the slide itself is not perfectly straight or flat, as usual). I did the milling in a haas mini mill with a renishaw probe built in. The machine has proven to be accurate within a couple tenths of a thousandth. Picked up the center of the slide for my Y axis and rear of the slide for my X axis. The sight fit as close to perfect as one could ask for, barely slips over the locating bosses and fits right into place. Well, I went to sight it in yesterday and it shoots about 3.5” To the right and 3” low at 15 yards. The sight is maxed out both left to right and up to down so i cant it any closer. The optic is truly straight with the slide (i stuck it back in the mill with the sight mounted and ran the indicator across it trying to figure out whats going on to no avail). My question for you guys is what do i do now? I could mill the Locating bosses off and mount the red dot crooked while shimming the rear up to bring it closer but i feel like thats not the correct way to do things. Maybe try to get a warranty replacement optic?

I do quality work, this is not my first time milling a slide for an optic, this is however the first time i haven't been able to get it sighted in. Its my personal gun by the way, i don't do this for other people. Ive attached a couple pictures for reference.

I do quality work, this is not my first time milling a slide for an optic, this is however the first time i haven't been able to get it sighted in. Its my personal gun by the way, i don't do this for other people. Ive attached a couple pictures for reference.