For a few years now I’ve been using a Strike Industries Glock that I assembled. I chose a set of Ameriglo Hackathorn sights for it, and I really liked them except for the fact that they always shot a little low. An issue that my other Glock didn’t have with similar ameriglo sights.

Wanting to finally be done with the low impacts I decided to swap them out for a different set of sights. And same issue again. Only conclusion I can come to is that something is just a little off with the alignment of the strike industries upper so I decided to be crafty and used my resources to shorten the front without marking it obvious that some half wit gun junkie went to town on it with power tools.

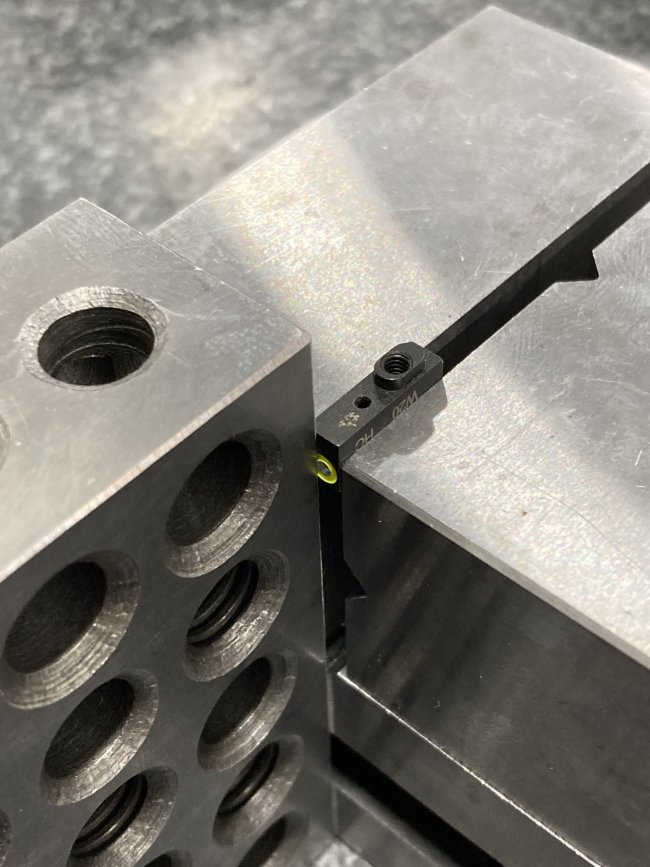

First I put it in a machinists vise.

Then used a 1 2 3 block to square it up.

To make sure it was flat I ran a dial indicator across the top. Turns out the squaring process was highly effective.

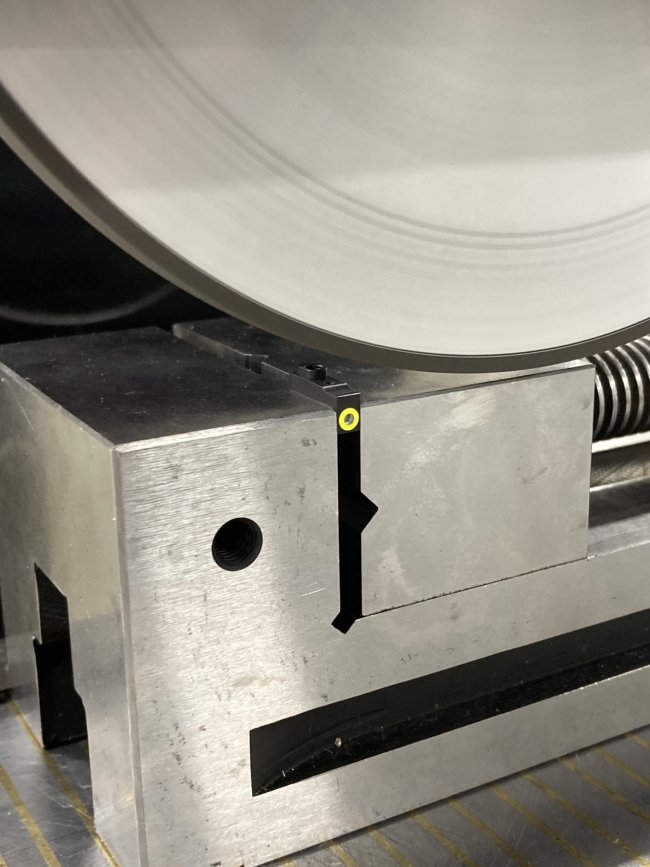

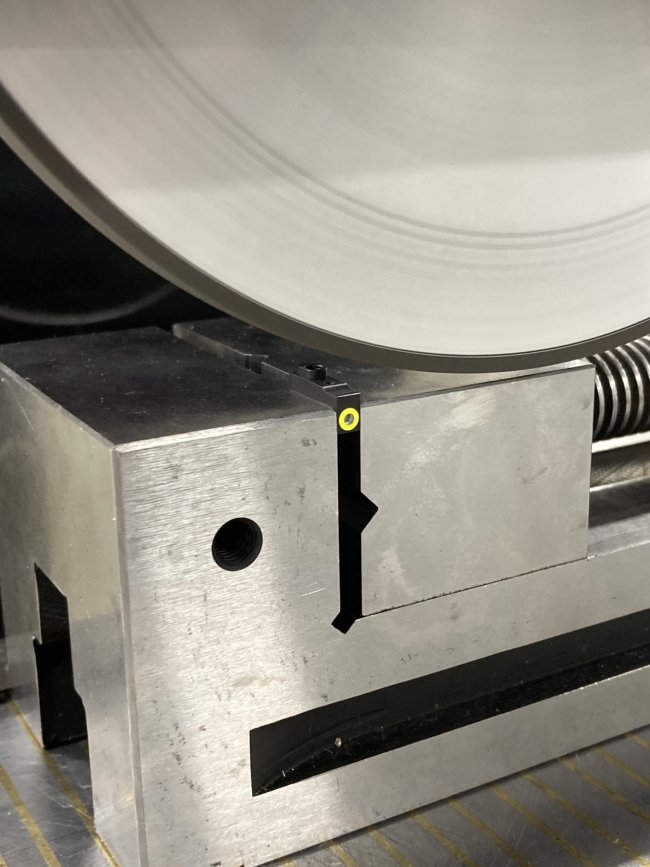

Took it over to an older manual grinder that you can find in most machine shops. They take some practice to get good with but 3 years of slaving in a screw machine plant more than equipped me for this simple job

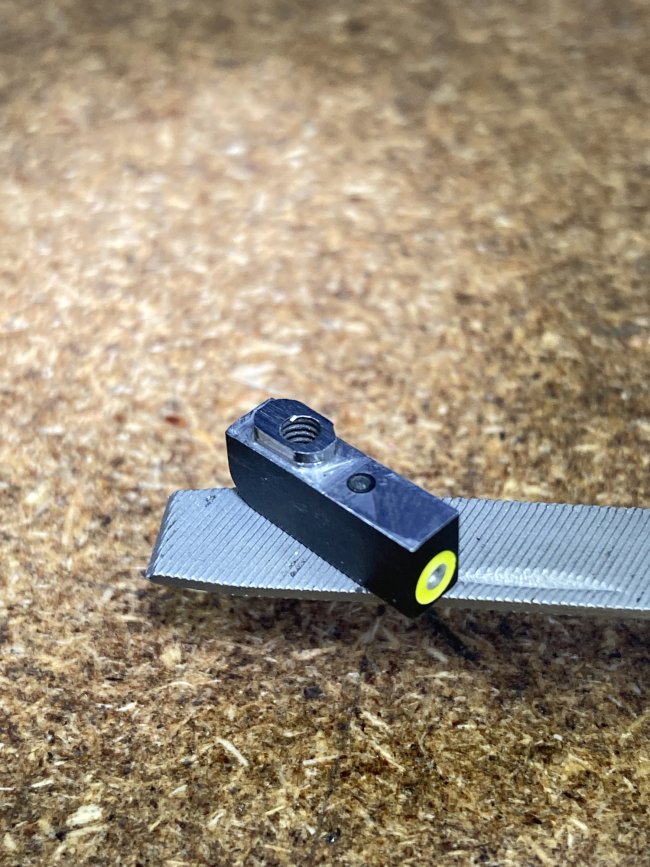

I measured the sight at .220” high and guessed I wanted to remove about 10% of it. Slowly brought the grind wheel down until it touched, then slowly reached my final depth.

In this application the .020” cut was not too much for the material so long as my feeds were very small increments.

And I went around the whole sight taking caution not to touch the threaded post in the center of the sight.

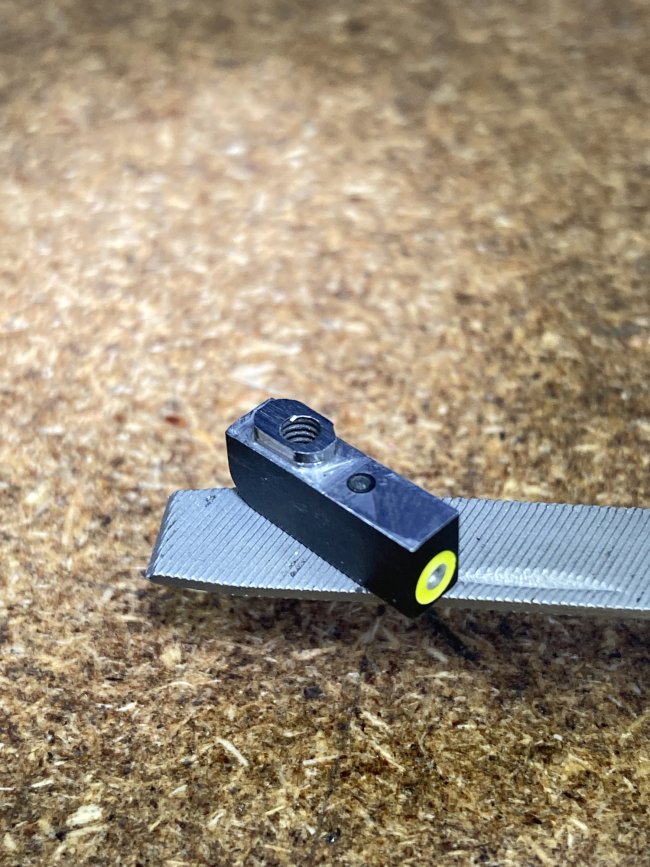

The initial grind left large radiuses near the post because my wheel wasn’t sharp enough. So I patiently started in with a file.

And here’s the file finished product.

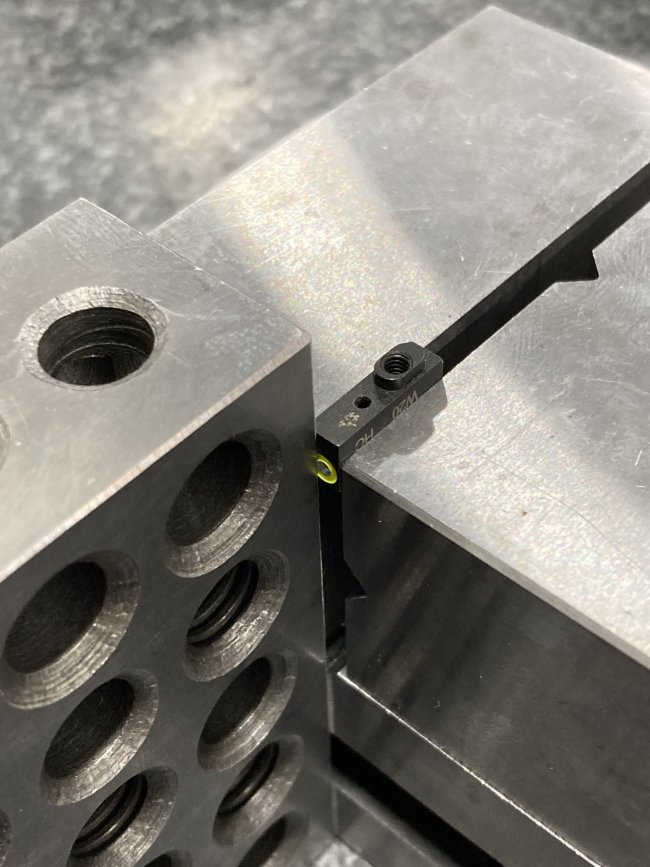

Fitting it to the slide I ran into the issue of the sight not getting fully tight. Realized the threaded post was protruding through its hole too far now. So I took it back to the grinder and removed .020” from the post and was able to get a good snug fit.

A little bit of touch up blue on the bottom and some loctite and this sight is range ready.

Best of all it it looks untouched! Hopefully this will get my impacts up to that nice 6 o clock hold I’m looking for.

Here’s the link to the original build for those curious.

www.indianagunowners.com

www.indianagunowners.com

Wanting to finally be done with the low impacts I decided to swap them out for a different set of sights. And same issue again. Only conclusion I can come to is that something is just a little off with the alignment of the strike industries upper so I decided to be crafty and used my resources to shorten the front without marking it obvious that some half wit gun junkie went to town on it with power tools.

First I put it in a machinists vise.

Then used a 1 2 3 block to square it up.

To make sure it was flat I ran a dial indicator across the top. Turns out the squaring process was highly effective.

Took it over to an older manual grinder that you can find in most machine shops. They take some practice to get good with but 3 years of slaving in a screw machine plant more than equipped me for this simple job

I measured the sight at .220” high and guessed I wanted to remove about 10% of it. Slowly brought the grind wheel down until it touched, then slowly reached my final depth.

In this application the .020” cut was not too much for the material so long as my feeds were very small increments.

And I went around the whole sight taking caution not to touch the threaded post in the center of the sight.

The initial grind left large radiuses near the post because my wheel wasn’t sharp enough. So I patiently started in with a file.

And here’s the file finished product.

Fitting it to the slide I ran into the issue of the sight not getting fully tight. Realized the threaded post was protruding through its hole too far now. So I took it back to the grinder and removed .020” from the post and was able to get a good snug fit.

A little bit of touch up blue on the bottom and some loctite and this sight is range ready.

Best of all it it looks untouched! Hopefully this will get my impacts up to that nice 6 o clock hold I’m looking for.

Here’s the link to the original build for those curious.

Fantastic Strike Industries Glock Build

I wanted to build a Glock 19 sized gun that was lighter and more premium WITHOUT having it look too "Gucci" with speed holes and gold gadgets stuck to it. This is what I came up with. The top end is a Strike Industries Liteslide and ARK barrel paired with a polymer OEM spring. Nicely...

Last edited: