Dog1

Master

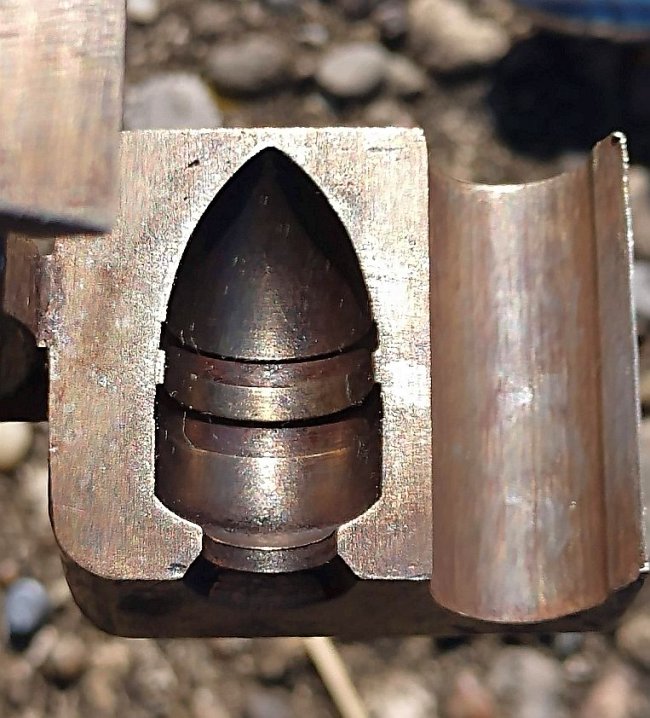

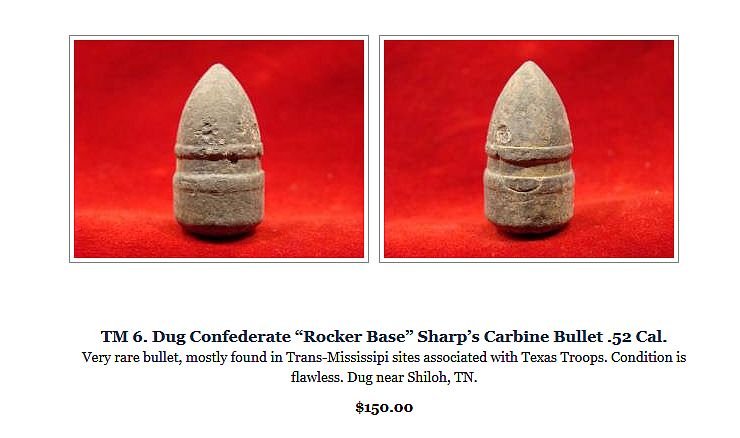

Just landed! I'm stoked to start making some periodish correct linen cartridges. I have the Eras Gone Richmond Laboratories bullet mold that I'm going to use for my first batch of cartridges. I'm going to get the other mold that has the ringtail or what some people call the Christmas tree bullet later on. Down in the garage I have a sheet of linen that has been sized with wallpaper sizer that is drying. I'm going to try first some goex and then I'm going to try the Shooters World black powder substitute.