This is a pretty good example of a Remington 1911, with the exception of the ejector being very recessed in the rear and the slide to frame not blending well together. So, I decided to fix that with an EGW long ejector and a fair amount of manual labor.

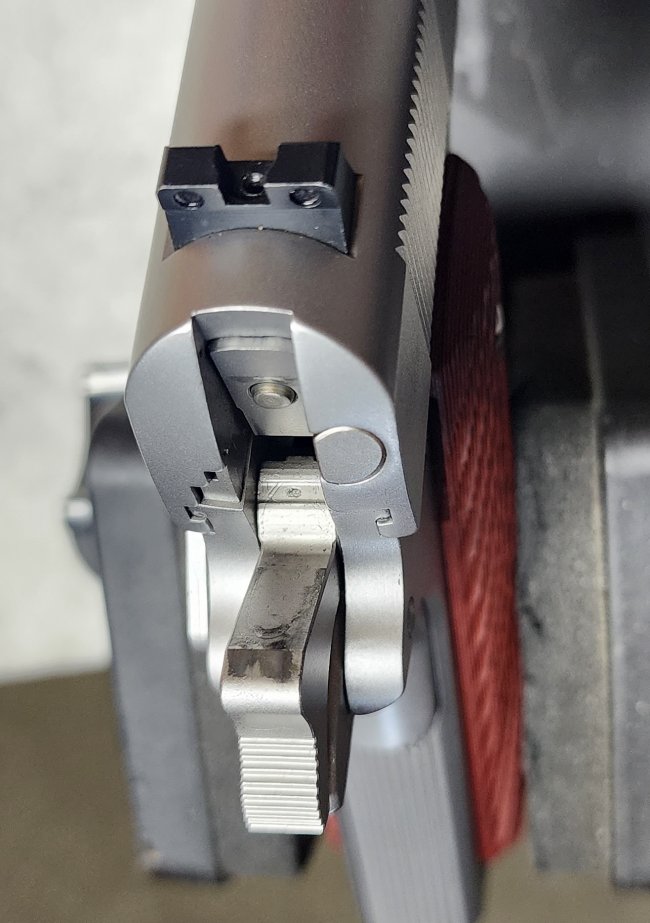

Here's the gun. I picked this up not too long ago from a LGS as "used", but it was actually never fired. So far, I've swapped in a SA long trigger, removed the 80 series parts and replaced with a TJ's .057" spacer, adjusted the trigger pull down to just over 3 pounds and added some Cool Hand G10 grips. It's pleasant to shoot, despite being a "GI style" gun without a lot of the bells & whistles.

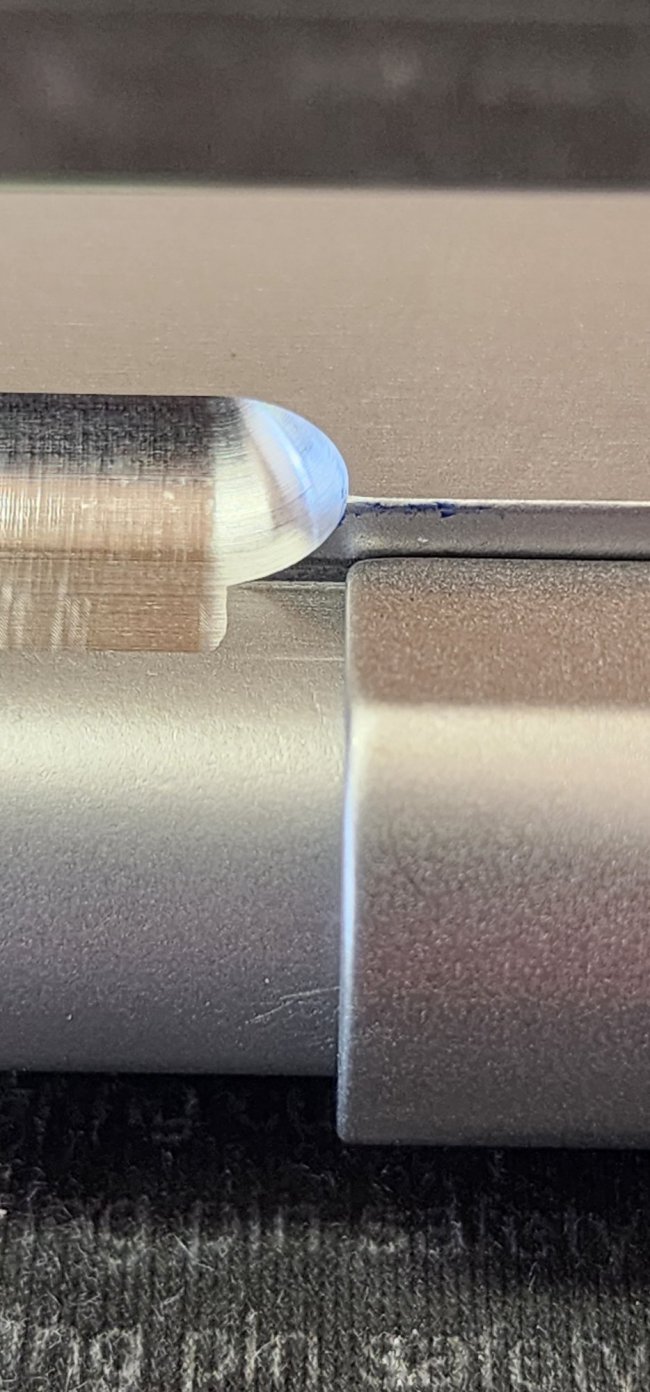

Ugly, very ugly in the rear.

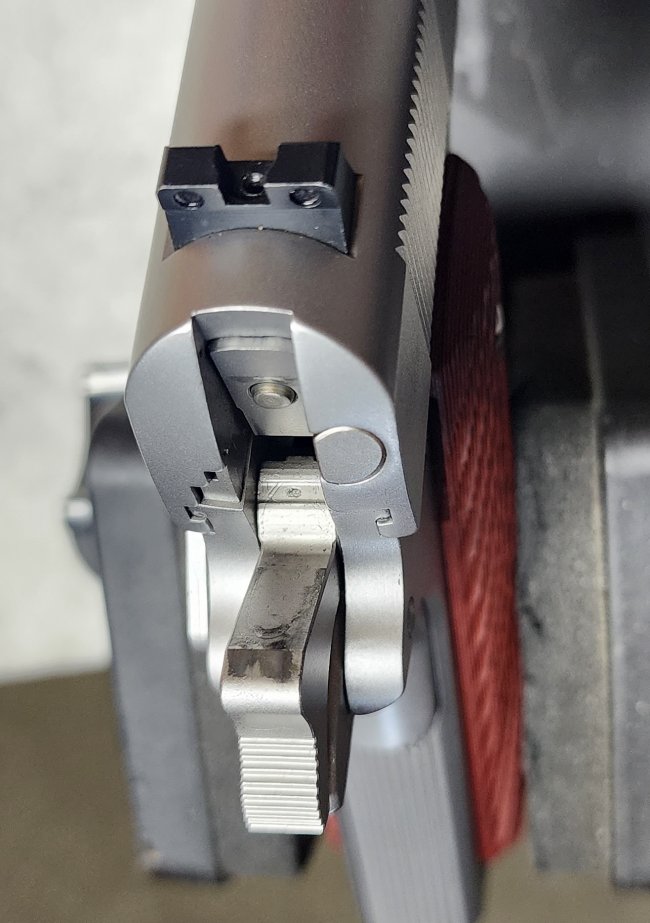

The original ejector was actually a little loose and it came out quite easy. You can see how much longer the EGW ejector is in comparison.

Marked the new ejector and began cutting a groove for the pin. I started my cut a little high, to help pull the ejector down when the pin is installed, and it worked well doing that.

New ejector in place and now sitting proud.

Time to get the belt sander out. Just kidding. I carefully used a Milwaukee Rotary tool ("Dremel") with coarse and fine sanding discs. This worked very well, I kept the speed manageable and keep a nice smooth sweeping motion. I followed that up with 600/800 grit sandpaper.

Here's the gun. I picked this up not too long ago from a LGS as "used", but it was actually never fired. So far, I've swapped in a SA long trigger, removed the 80 series parts and replaced with a TJ's .057" spacer, adjusted the trigger pull down to just over 3 pounds and added some Cool Hand G10 grips. It's pleasant to shoot, despite being a "GI style" gun without a lot of the bells & whistles.

Ugly, very ugly in the rear.

The original ejector was actually a little loose and it came out quite easy. You can see how much longer the EGW ejector is in comparison.

Marked the new ejector and began cutting a groove for the pin. I started my cut a little high, to help pull the ejector down when the pin is installed, and it worked well doing that.

New ejector in place and now sitting proud.

Time to get the belt sander out. Just kidding. I carefully used a Milwaukee Rotary tool ("Dremel") with coarse and fine sanding discs. This worked very well, I kept the speed manageable and keep a nice smooth sweeping motion. I followed that up with 600/800 grit sandpaper.