Good call jay, I rasseled the cowl off and now see that the motor needs to be removed first to access the linkage and congrats on biting your tongue on not pointing that out. It’s always best to let the kid learn a little on his own!Just pop the motor out, hit the switch and see if it runs while disconnected. Also manually move the wipers while it's out to see if there is any binding.

-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Windshield wiper problems

- Thread starter Jsomerset

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

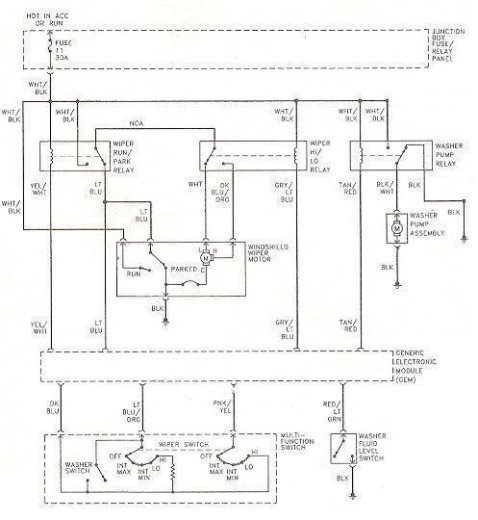

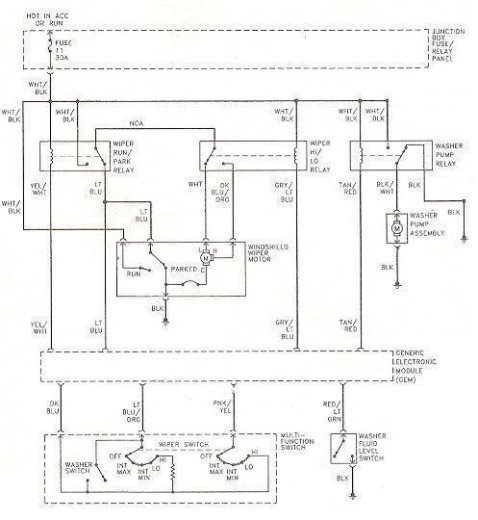

Unfortunately I no longer have access to wiring diagrams other than searching the internet. I have uploaded 2 wiring diagrams but they are not specifically for a 2005 F150, they are from previous years. One is from a 2000 the other is from a 1996 I believe. The common component on both, and probably on yours is the GEM (Generic Electronic Module) that controls the wiper operation. There are two ways to test the operation of the GEM, either with a scanner to monitor the inputs and outputs or through pin voltage testing. The scanner is much more efficient. Sometimes depending on the scanner if it has bi-directional controls you can command the wiper to operate aiding in diagnosis depending on how the module and wipers respond to the command. Pin voltage testing is more tedious as you have to test each wire in the module related to the wiper system going into the module and coming out of the module. I would still start at the motor. Regardless of wire colors, in low one should have voltage which goes away in any other switch position and the wipers should be running on low, same with the high speed wire. If neither has voltage, then check relay operation. When the wiper switch is turned to the low position you should hear/feel the run/park relay click , in the high position the high/low speed relay should click. If the relays do not work properly then you will need to check he GEM operation and the wires between the module and the relays. Again this is based on the wiring diagrams I have been able to find. You may have better luck searching for the exact diagram you need. Good luck.

Finally got the cowlings off but in pieces, the passenger side wiper arm was frozen on so I had to cut the cowling from around it . The linkage moves smoothly but the motor wil only turn in one direction so it’s new motor time. Thanks for all the advice fellas.

Clay Pigeon

Shooter

Finally got the cowlings off but in pieces, the passenger side wiper arm was frozen on so I had to cut the cowling from around it . The linkage moves smoothly but the motor wil only turn in one direction so it’s new motor time. Thanks for all the advice fellas.

Most simple wiper motors only run in one direction. It uses a mechanical reverse and not electrical to go into park. Speed control is mostly done with two sets of brushes and or a speed control board.

Im not saying the motor is not bad, but most wiper motors only run in one direction.

As close as I can tell there isn’t a way for the motor to make complete revolutions. There is also a magnet in the gear drive that must be for some kind of proximity sensor in the module cover.Most simple wiper motors only run in one direction. It uses a mechanical reverse and not electrical to go into park. Speed control is mostly done with two sets of brushes and or a speed control board.

Im not saying the motor is not bad, but most wiper motors only run in one direction.

Clay Pigeon

Shooter

As close as I can tell there isn’t a way for the motor to make complete revolutions. There is also a magnet in the gear drive that must be for some kind of proximity sensor in the module cover.

Most likely its in a mechanical park position, its a permanent magnet gear reduction motor == hard to manually turn without electricity being applied.

Turns out that 2005 was a bastard year on the wiper motor front. 05 was undead a reversing motor and the replacement was a one direction motor making complete revolutions as opposed to the back and forth original. New motor is about a pound and half lighter and shorter but bigger diameter. They changed the the mounting bracket to allow for the round and round system. The new motor and linkage is for years 06 to 2010. You would have thought that Ford would have made a note of it in their service manuals

Turns out that 2005 was a bastard year on the wiper motor front. 05 was undead a reversing motor and the replacement was a one direction motor making complete revolutions as opposed to the back and forth original. New motor is about a pound and half lighter and shorter but bigger diameter. They changed the the mounting bracket to allow for the round and round system. The new motor and linkage is for years 06 to 2010. You would have thought that Ford would have made a note of it in their service manualsAttachments

Last edited: