In the last couple of months, I've went from having no 2011 guns to having a Prodigy, a Staccato and now this pair of 2011 custom builds going.

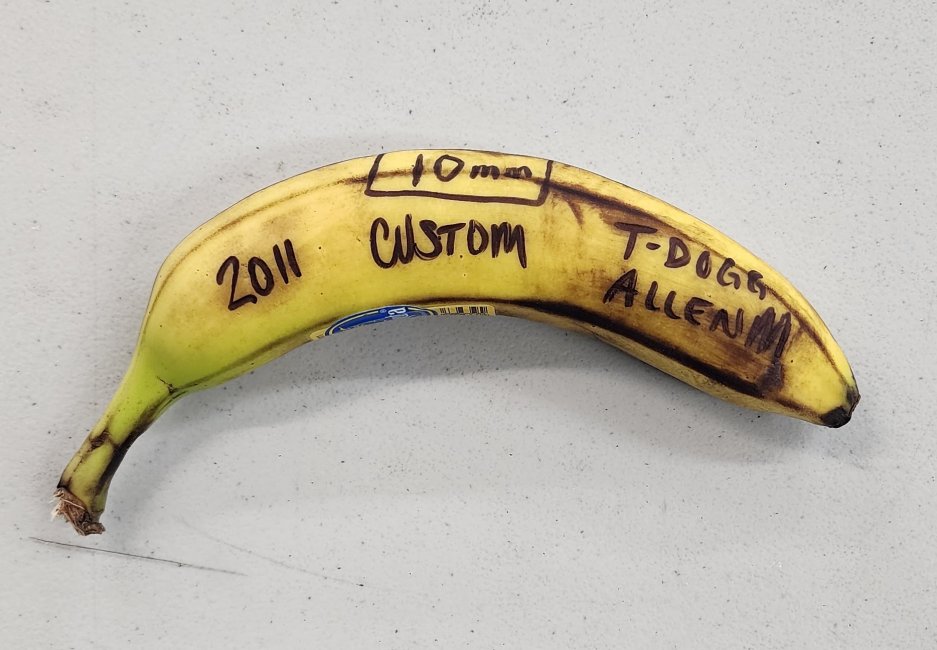

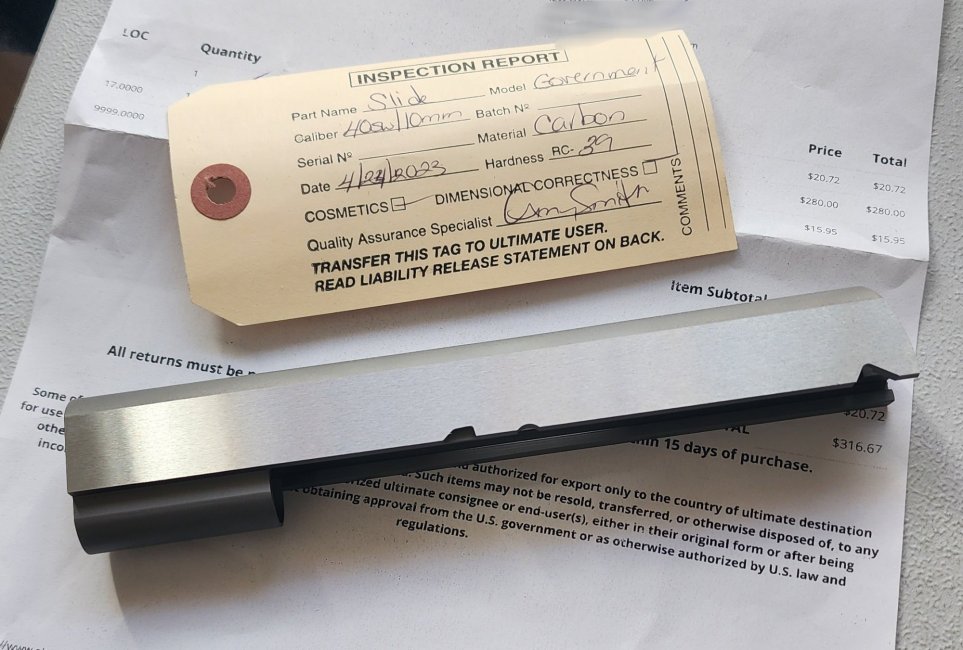

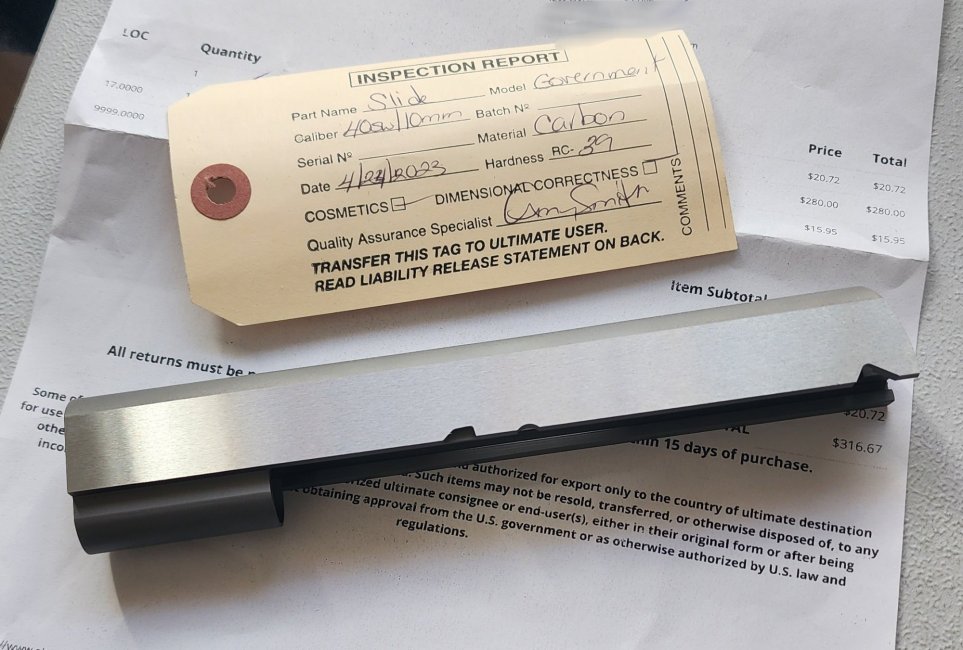

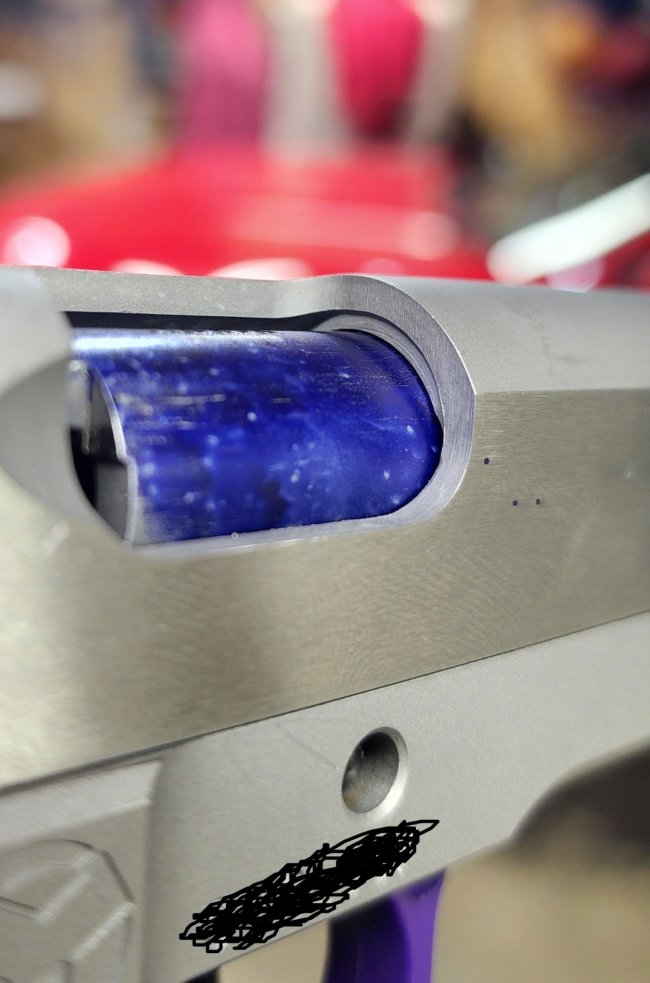

@AllenM made me a most generous offer. Buy a Cheely frame from him, pair it with whatever slide and barrel I want, spend a day at his shop for a fee and leave with a frame/slide/barrel fit together along with an education. Rest of the plan was to finish the gun at home on my own. The plan got a green light, and I decided on pairing up the frame with a Caspian carbon steel slab slide along with a 5" KKM Precision bull barrel in 10mm. Little did I know, Allen also had a factory built STI shortblock in .40 he wanted to sell as well (frame/slide/barrel/grip all fit together). A deal was made for that also and we reamed the chamber to 10mm as well. Then another barrel he had go tossed into the mix and the Cheely gun is now going to be dual caliber, 10mm and .357 Sig.

I'm missing a lot of photos, because frankly I forgot to take them and it really would have slowed the jam packed day down.

The fun went as such (this is condensed and might have a few things out of order):

- Debur frame and slide.

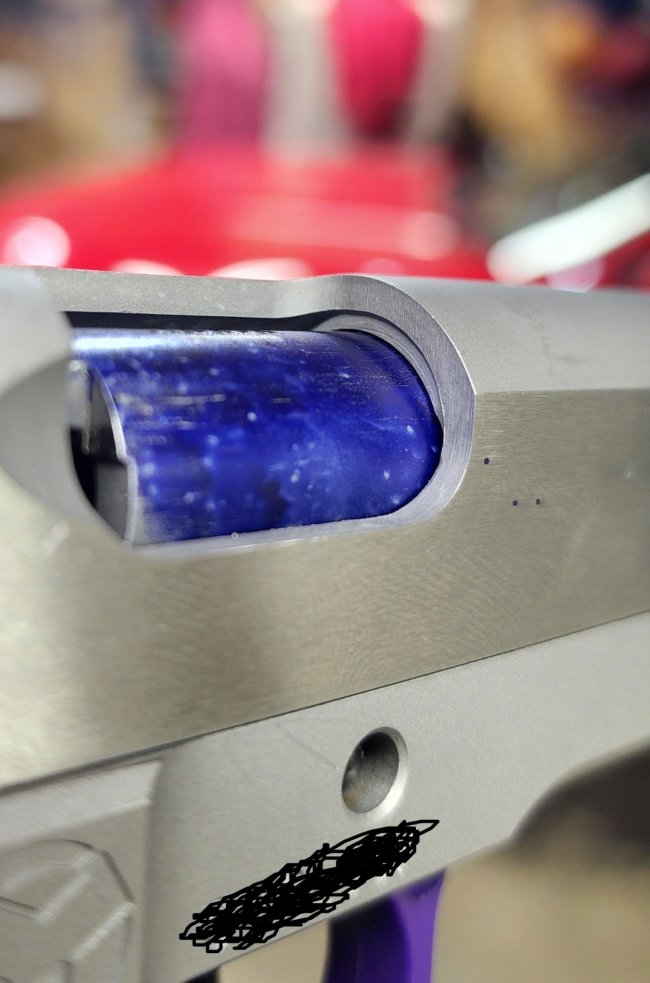

- Hone slide bore.

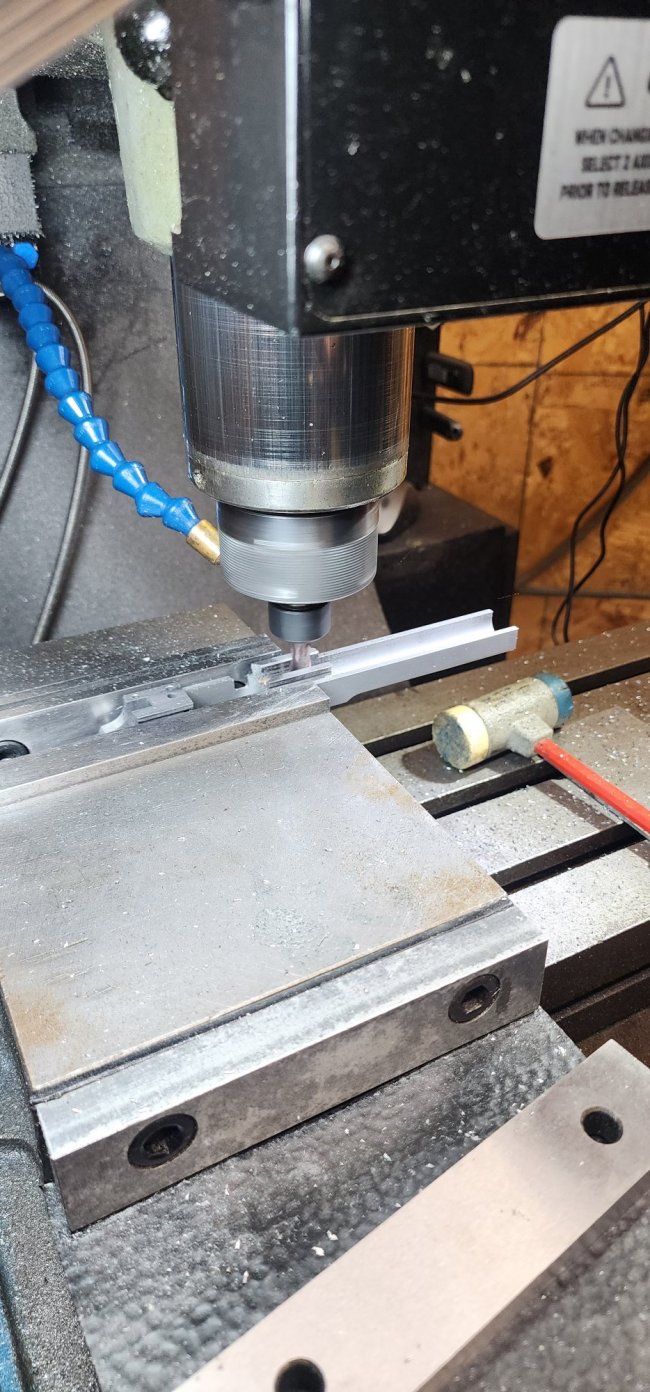

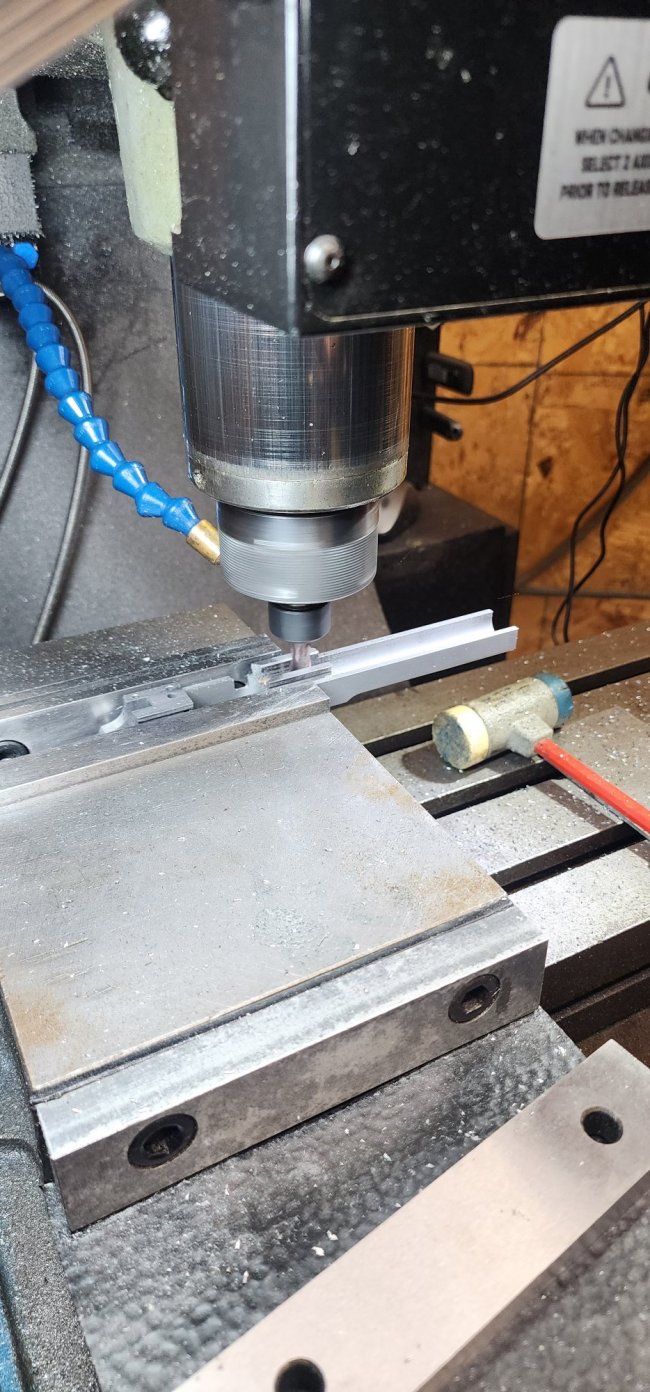

- Measure and cut rails on frame and slide.

- Lap slide and frame together.

- Mill frame for barrel to fit properly (Para/Clark style barrel).

- Measure and cut barrel hood width.

- Measure and cut barrel hood length.

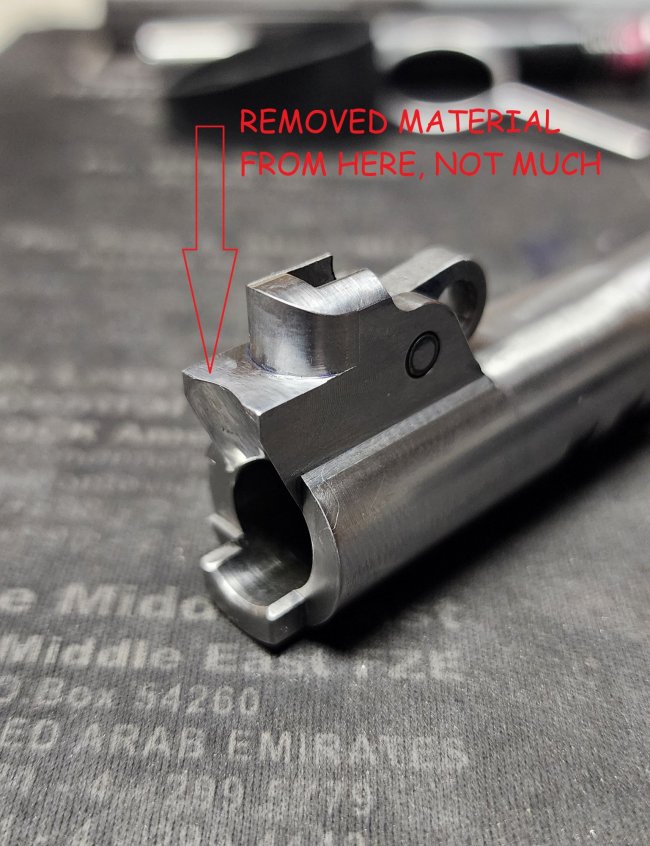

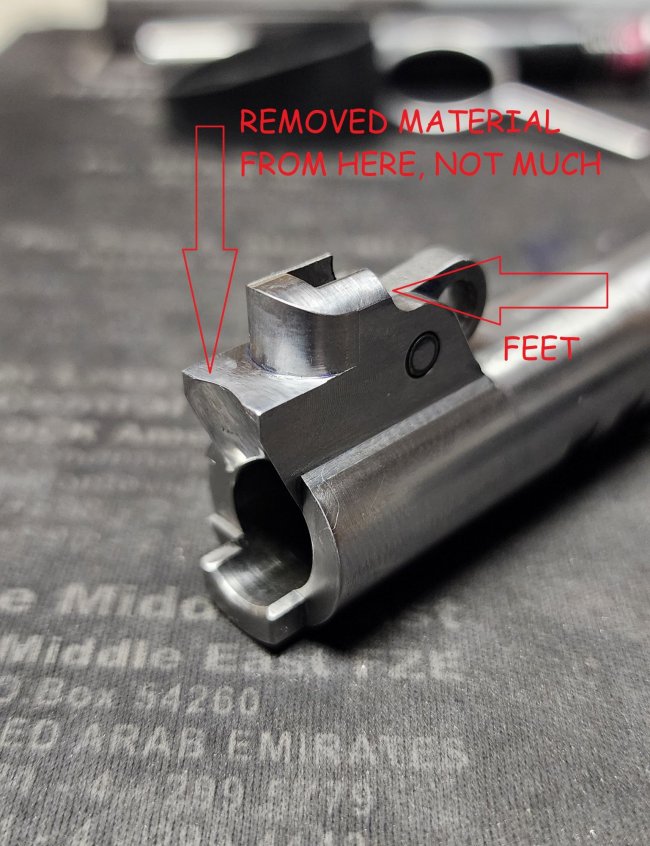

- Remove material from barrel to correct "springing" (barrel is "sprung" when in battery, do not want that).

- Measure and cut lower lugs on barrel to match slide stop pin diameter, verify thumb safety fits notch in slide.

- Chamber the barrel (finish ream to desired headspace).

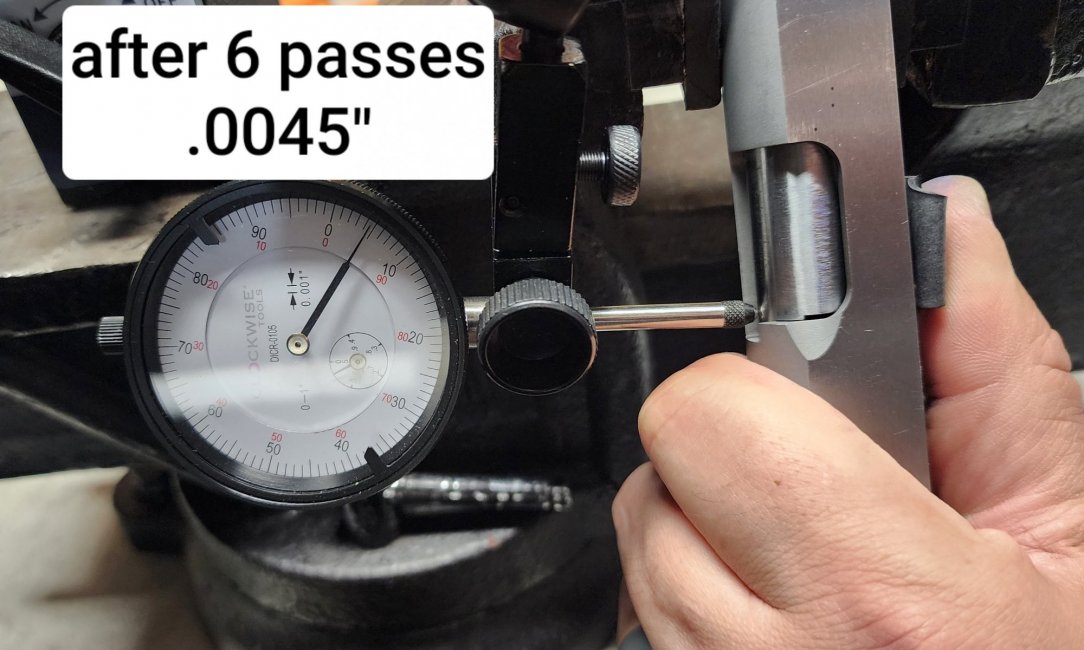

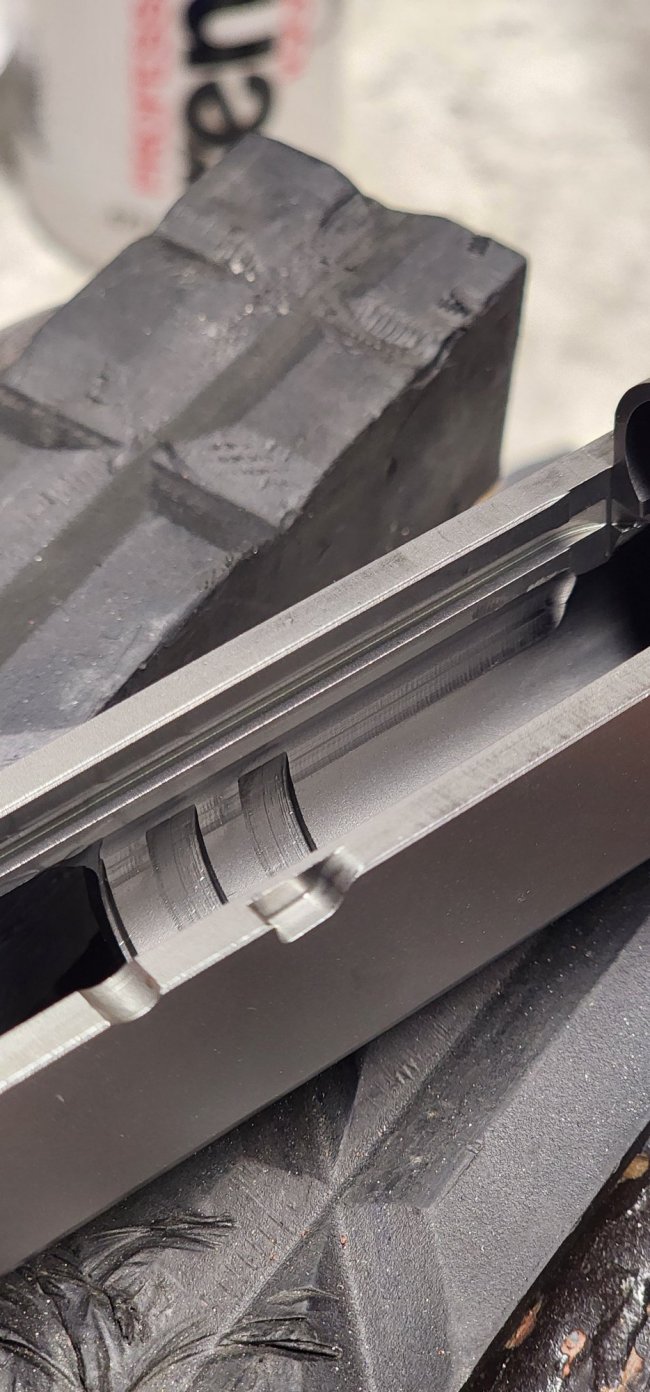

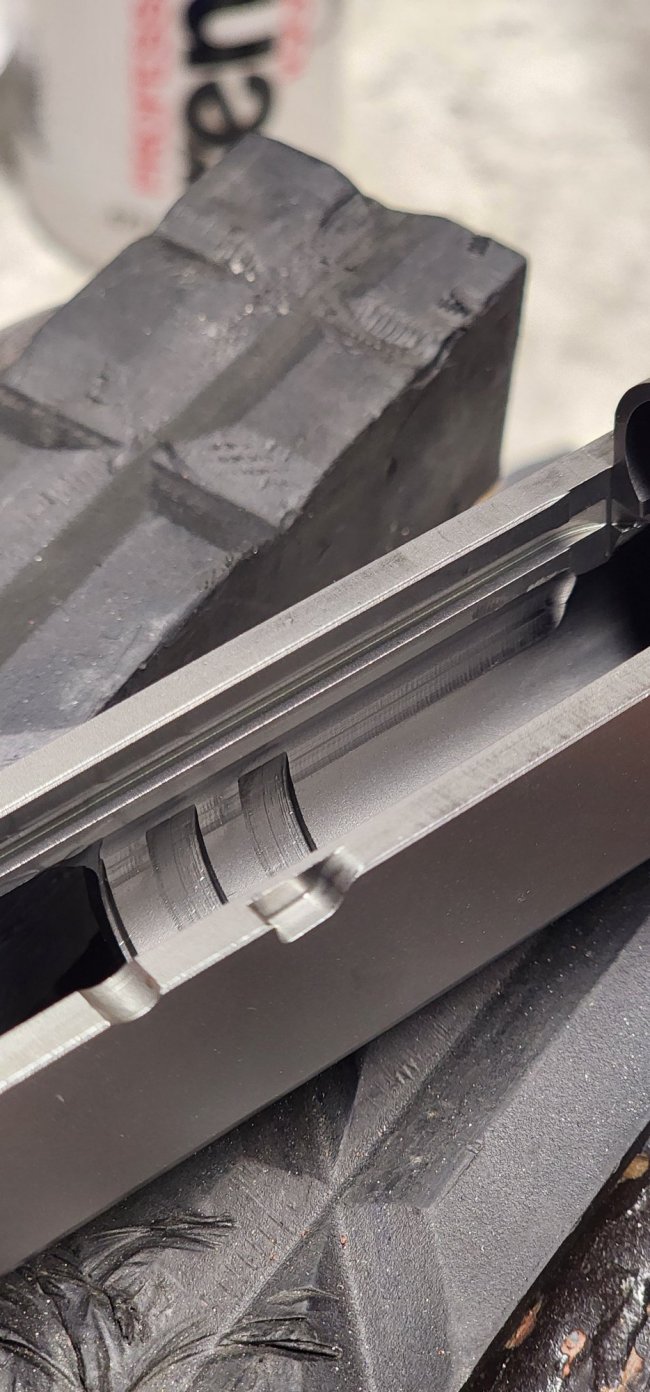

- Remove material from areas inside slide to give proper clearance for barrel to drop down when out of battery (prevents slide from dragging on barrel hood during cycling).

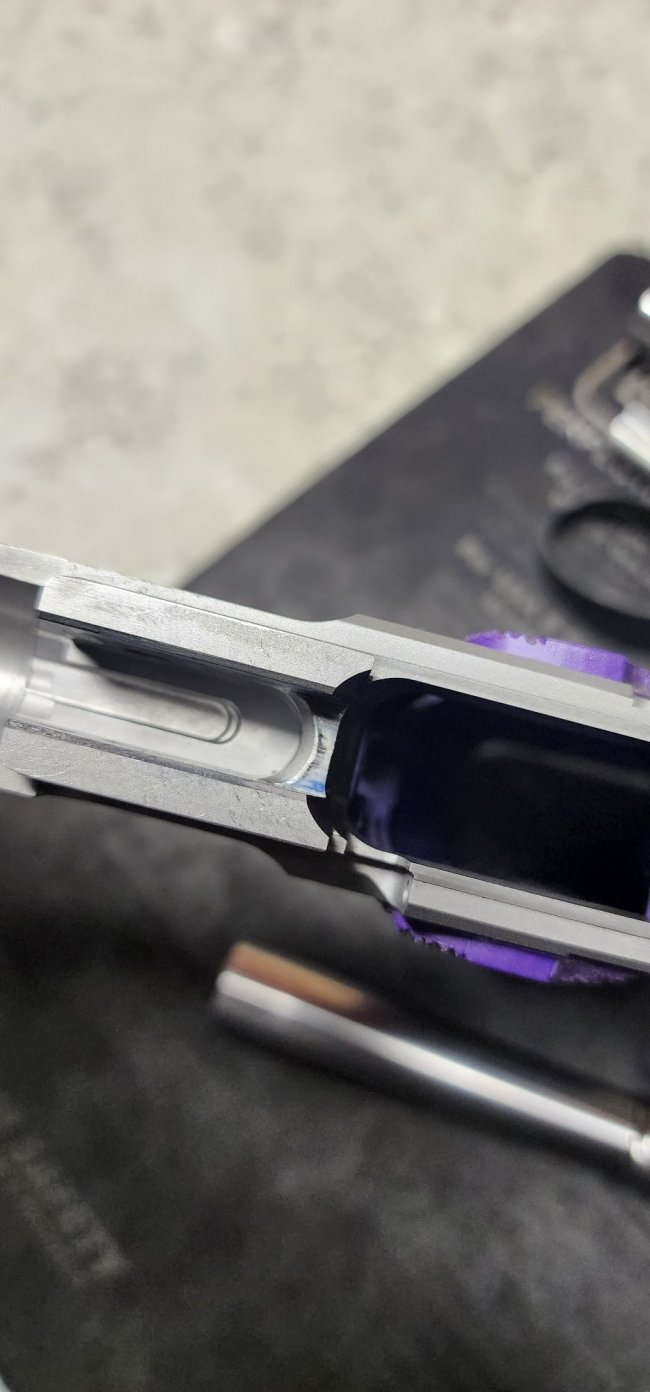

Afterwards at home, I finished working on the slide inside to give a little more clearance for the barrel.

I discovered the STI gun also needed some slide to barrel clearance, so I worked on that gun as well. Using what Allen taught me, it took no time at all.

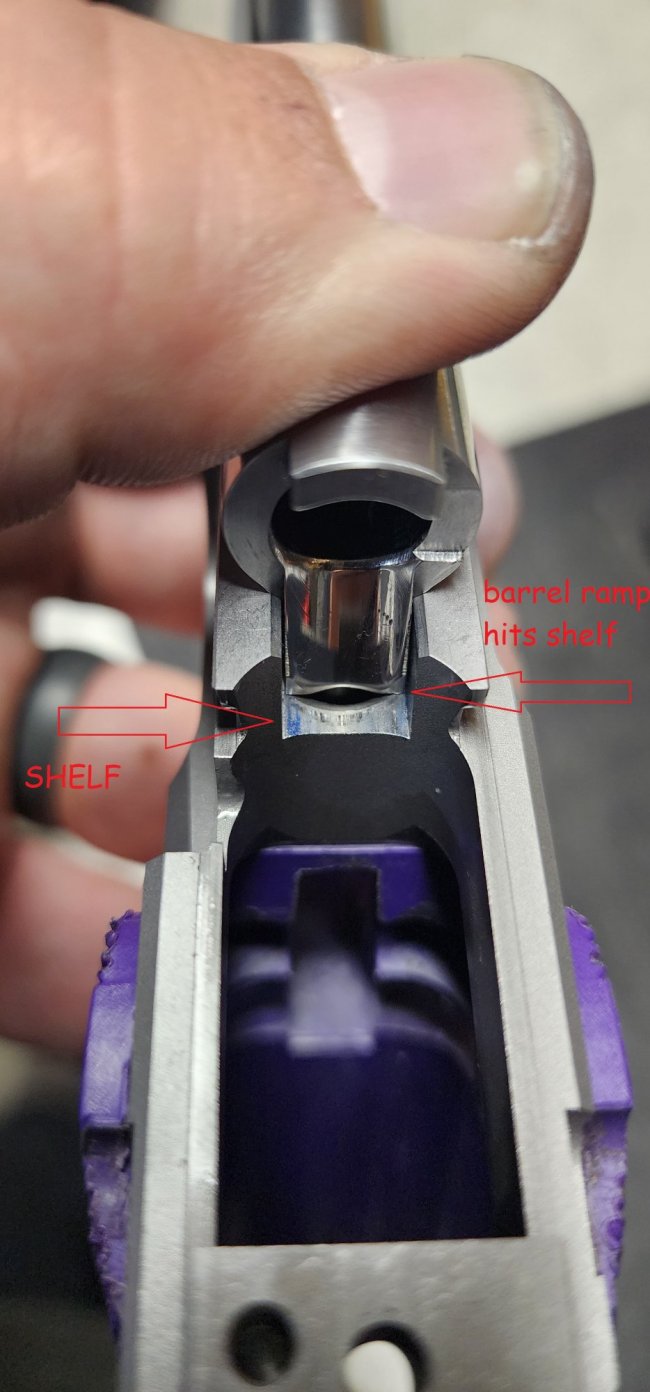

You have to make a channel just below the locking lugs for the barrel to drop down. It also hits on the recoil spring plug tunnel. More on this later.

The area below the barrel ramp on the STI gun needed a little material removed, to allow the barrel to sit against the cradle on the frame. More on that later.

@AllenM made me a most generous offer. Buy a Cheely frame from him, pair it with whatever slide and barrel I want, spend a day at his shop for a fee and leave with a frame/slide/barrel fit together along with an education. Rest of the plan was to finish the gun at home on my own. The plan got a green light, and I decided on pairing up the frame with a Caspian carbon steel slab slide along with a 5" KKM Precision bull barrel in 10mm. Little did I know, Allen also had a factory built STI shortblock in .40 he wanted to sell as well (frame/slide/barrel/grip all fit together). A deal was made for that also and we reamed the chamber to 10mm as well. Then another barrel he had go tossed into the mix and the Cheely gun is now going to be dual caliber, 10mm and .357 Sig.

I'm missing a lot of photos, because frankly I forgot to take them and it really would have slowed the jam packed day down.

The fun went as such (this is condensed and might have a few things out of order):

- Debur frame and slide.

- Hone slide bore.

- Measure and cut rails on frame and slide.

- Lap slide and frame together.

- Mill frame for barrel to fit properly (Para/Clark style barrel).

- Measure and cut barrel hood width.

- Measure and cut barrel hood length.

- Remove material from barrel to correct "springing" (barrel is "sprung" when in battery, do not want that).

- Measure and cut lower lugs on barrel to match slide stop pin diameter, verify thumb safety fits notch in slide.

- Chamber the barrel (finish ream to desired headspace).

- Remove material from areas inside slide to give proper clearance for barrel to drop down when out of battery (prevents slide from dragging on barrel hood during cycling).

Afterwards at home, I finished working on the slide inside to give a little more clearance for the barrel.

I discovered the STI gun also needed some slide to barrel clearance, so I worked on that gun as well. Using what Allen taught me, it took no time at all.

You have to make a channel just below the locking lugs for the barrel to drop down. It also hits on the recoil spring plug tunnel. More on this later.

The area below the barrel ramp on the STI gun needed a little material removed, to allow the barrel to sit against the cradle on the frame. More on that later.