Can't be stuck if its liquid!I have a fool proof method for stuck. Heat it cherry red, quench it completely with a garden hose. I can usually remove it with my fingers after a 1/4 turn.

Off topic but put that in your back pocket.

-

Be sure to read this post! Beware of scammers. https://www.indianagunowners.com/threads/classifieds-new-online-payment-guidelines-rules-paypal-venmo-zelle-etc.511734/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric impact socket adapters

- Thread starter phylodog

- Start date

The #1 community for Gun Owners in Indiana

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

Only thing I can think of, it burns the rust off. I'll ask my molten metal friend. @actaeon277Can't be stuck if its liquid!

I assumed he was. A few posts down from yours confirmed my assumption.At this point how do you know he's using a 1/4" impact driver?

Just as easily he could be putting those 1/4 x 1/2" bits in a 1/2" Milwaukee hole shooter low speed drill.

Snap goes the adapter.

Hes was post #72 LOLI assumed he was. A few posts down from yours confirmed my assumption.

Since you got your problem solved can you ask the mods to close this thread? Someone's head is going to explode if you don't.Would've bought the Menards brand but I was passing Lowe's on my way home and now all of my problems are solved. Thanks for the recommendations.

liquid metal cleans everythingOnly thing I can think of, it burns the rust off. I'll ask my molten metal friend. @actaeon277

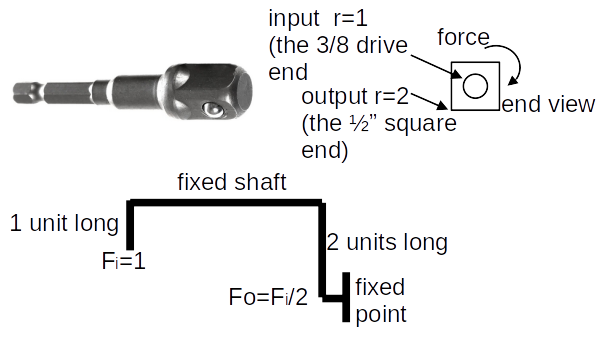

This would be true if the twisting force was coming from the fastener, but it is coming from the driver.View attachment 340632

If r is bigger keeping F the same, t goes up.

Repeating myself ad nausium without comprehension.

According to my Mechanical PE friend, I am correct.

So if my chosen point is 1/2" from the center (r) of a shaft, I can cause twice the torsional deflection than I can 1/4" from the center with the same amount of force.

A 1 foot long breaker bar can twist an extension twice as far as a 6" breaker bar exerting the same amount of force to the end of it.

Here is my last attempt to explain myself.

My theory is that a "higher quality" hardened shaft is more brittle and will tent to snap if stressed vs. a "lower quality" shaft made from a more ductile material that would simply deform (twist).

While the absolute torque applied to the fastener (output) is the same as the input, the stress within the shaft is greater due to the larger size (radius) of the output.

This is how a torque wrench works, 1 lb of force applied to a shaft 1 ft from output causes 1 ft-lb force at the output.

1 lb. of force applied to a shaft 2 ft long causes 2 ft-lbs at output giving mechanical advantage.

Assume the shaft is fixed so it cannot move from it’s plane and only rotate

Input lever is 1 unit long

Output lever is 2 units long attached to a fixed point that cannot move (simulating a stuck fastener)

Force is conserved regardless of direction so it works inversely in reverse.

1 unit of force applied to input causes ½ units at output point

Conversely, 1 unit of force applied to the output end would cause 2 units of force at input end (minus the momentary torsional loss of the shaft until it springs back to equilibrium)

In this exaggerated version of the adapter, if the input is .25” dia. and the output is .5” dia. (the outermost surface of ½” square drive) to get 1 unit of force out, you must apply 2 units of force in, doubling the torsional stress on the shaft.

Prove me wrong

My theory is that a "higher quality" hardened shaft is more brittle and will tent to snap if stressed vs. a "lower quality" shaft made from a more ductile material that would simply deform (twist).

While the absolute torque applied to the fastener (output) is the same as the input, the stress within the shaft is greater due to the larger size (radius) of the output.

This is how a torque wrench works, 1 lb of force applied to a shaft 1 ft from output causes 1 ft-lb force at the output.

1 lb. of force applied to a shaft 2 ft long causes 2 ft-lbs at output giving mechanical advantage.

Assume the shaft is fixed so it cannot move from it’s plane and only rotate

Input lever is 1 unit long

Output lever is 2 units long attached to a fixed point that cannot move (simulating a stuck fastener)

Force is conserved regardless of direction so it works inversely in reverse.

1 unit of force applied to input causes ½ units at output point

Conversely, 1 unit of force applied to the output end would cause 2 units of force at input end (minus the momentary torsional loss of the shaft until it springs back to equilibrium)

In this exaggerated version of the adapter, if the input is .25” dia. and the output is .5” dia. (the outermost surface of ½” square drive) to get 1 unit of force out, you must apply 2 units of force in, doubling the torsional stress on the shaft.

Prove me wrong

Last edited:

If I set my torque wrench at 100 foot pounds and then add a 2 foot extension, am I applying 200 foot pounds of torque to a lug nut?This is how a torque wrench works, 1 lb of force applied to a shaft 1 ft from output causes 1 ft-lb force at the output.

1 lb. of force applied to a shaft 2 ft long causes 2 ft-lbs at output giving mechanical advantage.

No, not what I said. It's not just an extension but an adapter from a smaller end to a larger end. And, like I explained above, the absolute torque transferred does not change, but the torsion across the adapter shaft does increase in proportion to the size differential of the ends.If I set my torque wrench at 100 foot pounds and then add a 2 foot extension, am I applying 200 foot pounds of torque to a lug nut?

Last edited:

So if the tool puts out 100 ft lbs of torque and it takes 200 ft lbs of torque to turn the fastener,

the adapter will break before before the tool stalls out?

I'm betting the fastener stops and the tool tries to spin because it is not fixed solid. And if it is fixed solid, everything will come to a stop

the adapter will break before before the tool stalls out?

I'm betting the fastener stops and the tool tries to spin because it is not fixed solid. And if it is fixed solid, everything will come to a stop

But if the tool is capable of putting out 200 pounds of torque, but you’re using a measly quarter inch adapter, that torque will overcome that skinny shaft and break it. to apply 200 pounds torque to an object you would likely need a much thicker stronger shaft.So if the tool puts out 100 ft lbs of torque and it takes 200 ft lbs of torque to turn the fastener,

the adapter will break before before the tool stalls out?

I'm betting the fastener stops and the tool tries to spin because it is not fixed solid. And if it is fixed solid, everything will come to a stop

The OP stated that he was snapping adapters, which means his tool was capable of applying more torque than a quarter inch shaft could handle. Apparently, the tool the OP has would benefit having a larger chuck

This is why half inch extensions are thicker than 3/8 inch extensions, because half inch tools are capable of applying much more torque.

I hope this explanation makes sense.

Last edited:

I don't think this is wrong, but it has little bearing on the OP's problem. His problem is that the adapter was breaking before the limit of his tool. He was asking for adapter recommendations that would match his tool. Obviously any tool will break if pushed beyond its limits and no one has argued that all 1/2" fasteners can be removed/installed with a 1/4" tool.Here is my last attempt to explain myself.

My theory is that a "higher quality" hardened shaft is more brittle and will tent to snap if stressed vs. a "lower quality" shaft made from a more ductile material that would simply deform (twist).

While the absolute torque applied to the fastener (output) is the same as the input, the stress within the shaft is greater due to the larger size (radius) of the output.

This is how a torque wrench works, 1 lb of force applied to a shaft 1 ft from output causes 1 ft-lb force at the output.

1 lb. of force applied to a shaft 2 ft long causes 2 ft-lbs at output giving mechanical advantage.

Assume the shaft is fixed so it cannot move from it’s plane and only rotate

Input lever is 1 unit long

Output lever is 2 units long attached to a fixed point that cannot move (simulating a stuck fastener)

Force is conserved regardless of direction so it works inversely in reverse.

1 unit of force applied to input causes ½ units at output point

Conversely, 1 unit of force applied to the output end would cause 2 units of force at input end (minus the momentary torsional loss of the shaft until it springs back to equilibrium)

View attachment 340749

In this exaggerated version of the adapter, if the input is .25” dia. and the output is .5” dia. (the outermost surface of ½” square drive) to get 1 unit of force out, you must apply 2 units of force in, doubling the torsional stress on the shaft.

Prove me wrong

See my post just before yours where I do address this.His problem is that the adapter was breaking before the limit of his tool. He was asking for adapter recommendations that would match his tool. Obviously any tool will break if pushed beyond its limits and no one has argued that all 1/2" fasteners can be removed/installed with a 1/4" tool.

The OP stated that he was snapping adapters, which means his tool was capable of applying more torque than a quarter inch shaft could handle. Apparently, the tool the OP has would benefit having a larger chuckso he wouldn't need an adapterso he could use an appropriately strong adapter.

Last edited:

Not for the question I asked, which is why this thread jumped the shark with rockets on its back.The "right" answer would seem to be a 3/8th" drive impact gun and a 1/2" impact gun.

thunderchicken

Grandmaster

I'm late to the party, but if you don't mind spending a few extra bucks for quality go online and buy the adapters from Snap-on.

I have a few cordless impacts with the 1/4" quick change bit system. The Snap-on adapters have never let me down.

I've used them in the cop shop, at home and at the racetrack. I try to take care of my tools but reality is they also get abused.

Some keep harping on using the right tool or torque values relative to driver size. Maybe too smart for their own good. Regardless what size the driver anvil is, the cordless tool still has a maximum torque rating. Sometimes you may need to break a fastener loose slightly before zipping it off with the cordless driver. Then again, sometimes you will need to do a final torque on more critical stuff after tightening. But, I'm sure you're smart enough to know that already, so not trying to insult your intelligence.

I have a few cordless impacts with the 1/4" quick change bit system. The Snap-on adapters have never let me down.

I've used them in the cop shop, at home and at the racetrack. I try to take care of my tools but reality is they also get abused.

Some keep harping on using the right tool or torque values relative to driver size. Maybe too smart for their own good. Regardless what size the driver anvil is, the cordless tool still has a maximum torque rating. Sometimes you may need to break a fastener loose slightly before zipping it off with the cordless driver. Then again, sometimes you will need to do a final torque on more critical stuff after tightening. But, I'm sure you're smart enough to know that already, so not trying to insult your intelligence.

Latest posts

-

-

-

-

NWI INGO General Thread #27 - Fresh Pink Air On US-30 smells like...

- Latest: Ballstater98

-

Staff online

-

KellyinAvonBlue-ID Mafia Consigliere

Members online

- Squid556

- glank09

- ROLEXrifleman

- Loco179

- sp3worker

- MrMunster

- Joniki

- KellyinAvon

- flyingsquirrel

- loudgroove

- singlesix

- JR50

- FreeLand

- tangleridgeslim

- Fallschirmjaeger

- Dwight

- DoggyDaddy

- JHB

- Mice54

- Twinsen

- indyartisan

- Piezak

- BeDome

- Cavman

- Magyars

- 2WheelinTrucker

- rbhargan

- Thor

- wtburnette

- jsharmon7

- OneBadV8

- 812 rimfire

- Relax_36

- Nazgul

- Jim5528

- Firehawk

- j706

- sescbo

- papa6x

- thegeez

- Squirt239

- Tradesylver

- ws6duramax

- sixty8firebird1

- mike4sigs

- purdue98

- Good on paper

- Rafterman

- led4thehed2

- 63PGP

Total: 1,484 (members: 103, guests: 1,381)